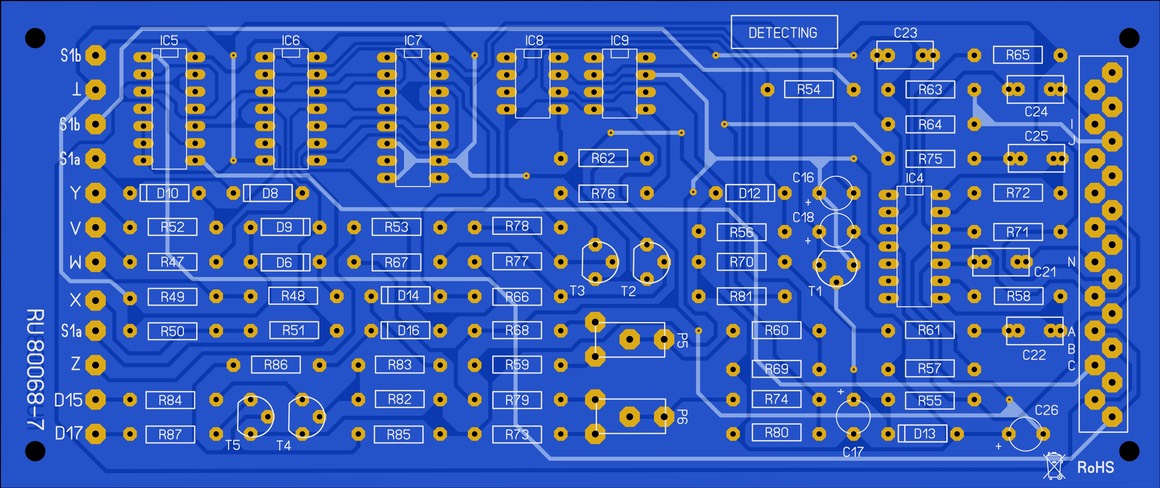

PCB reference RU80068.7

Estimated building time: 2 hours

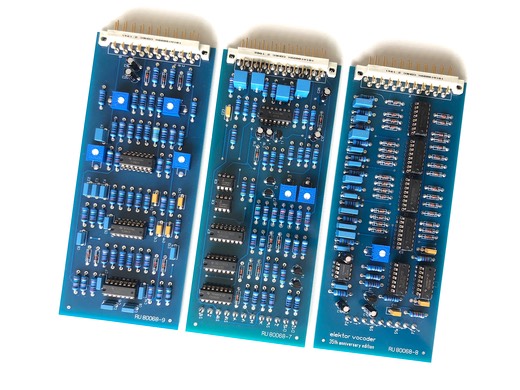

To complete this step the PCB with reference RU80068.7 is required:

Sort all required components as indicated in the BOM.

Bend the resistors so that they fit neatly right away and solder them on the right position:

There are some typo's on the silkscreen: R56 should be read as R65 and R50 on the right side of the PCB should be read as R60. This is only applicable for the prototyping boards.

Bend now diodes so that they fit neatly right away. Do not mix the 1N4148 standard diode with the zener diodes as they look allmost the same:

Solder the diodes on the right position. Note the direction of the black line (component) and tabbed indication (silkscreen). Do not reverse the polarity of these components:

Put the 21 pin connector to the board, do not exert any excessive force. Solder only pin 1 and pin 21 and check for a right angle. Correct if necessary and solder all remaining pins:

Add the IC sockets by soldering only 1 pin. Check the direction and alignment of the IC sockets before soldering the remaining pins. Also plug the corresponding IC's into the IC sockets, double check the direction of the notch to avoid destroyed IC's afterwards.

This is how the detecting interface looks now:

Insert the transistors, do not mix the BC547 and BC548, they look exactly the same. Solder only 1 of the legs, this allows lining up the components. Watch the direction of the transistors, correct if necessary and solder the remaining legs:

Thereafter add the trimpots:

Insert the electrolytic capacitors (e-caps), check the values according to the BOM. Solder only 1 of both legs, this allows lining up the components. Watch the polarity (the long wire is the positive), correct if necessary and solder all remaining legs:

Add the film capacitors as specified in the BOM. Solder only 1 of both legs, this allows lining up the components. Crrect if necessary and solder all remaining legs:

Finally use a pliers to press all solder pins into the PCB. The solder pins should have a diameter of 1 mm, the holes in the PCB have the same size. So firmly press the pins into the right position:

Thoroughly clean the PCB using flux cleaner and check for bad soldering or tin bulbs:

Well done

Congratulations, you have finished the detecting interface, click here to navigate back to the building guide.