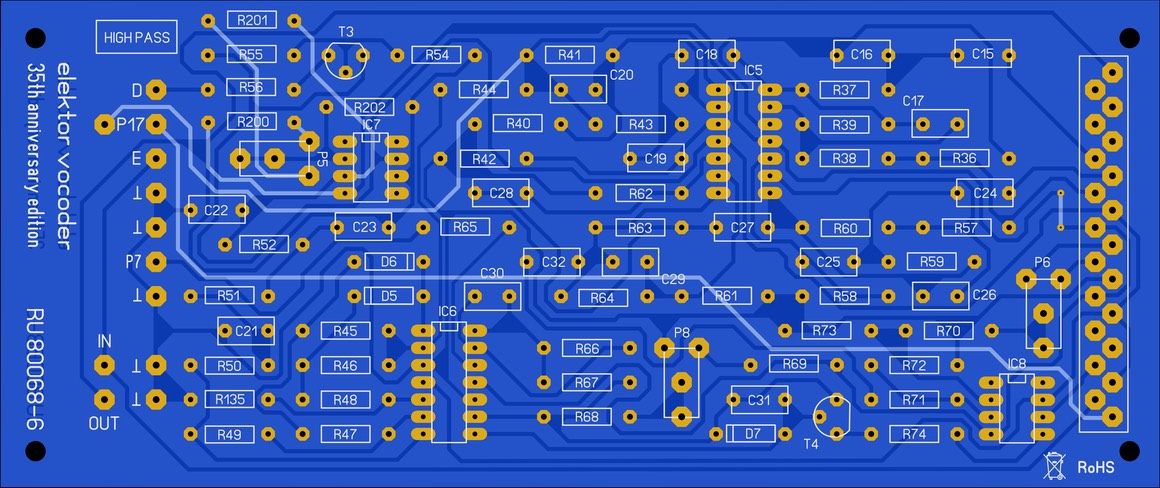

PCB reference RU80068.6

Estimated building time: 1,5 hours

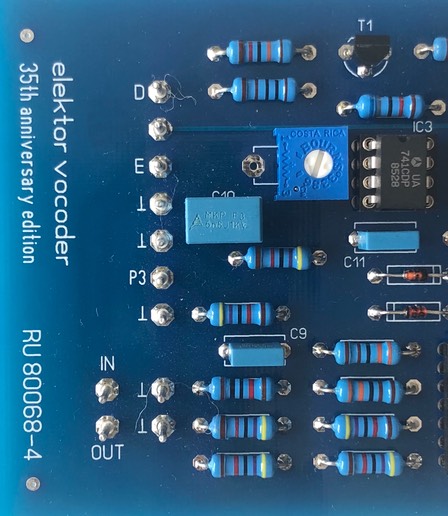

To complete this step the PCB with reference RU80068.6 is required:

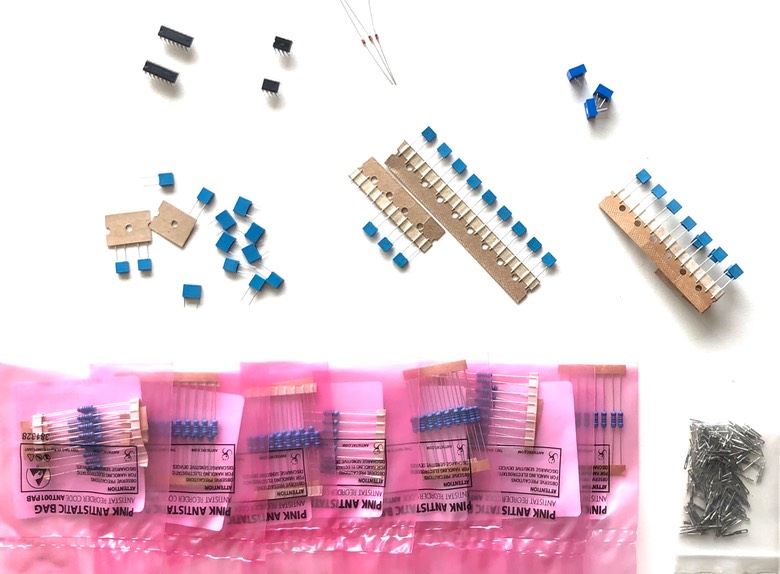

Sort all required components as indicated in the BOM:

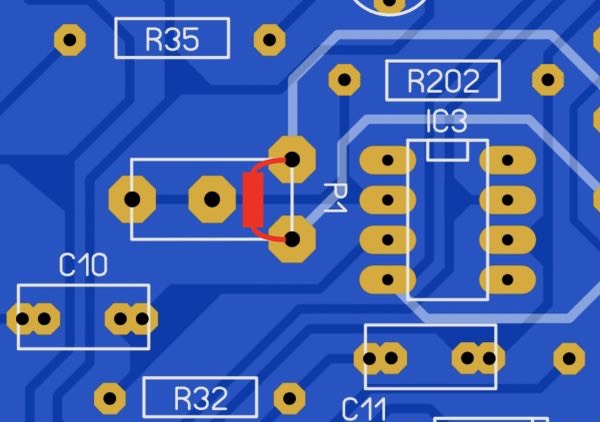

The following patch is required on the production run boards:

Cut the trace (red cross on the picture) between R201 and IC7 (component side of the PCB).

Wire bridge R201 and R55 (green connection on the picture).

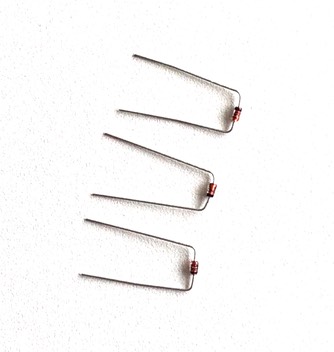

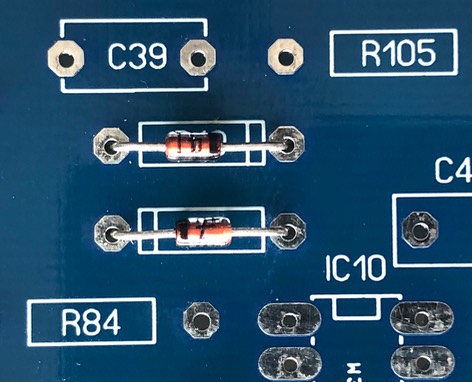

Bend the diodes so that they fit neatly right away:

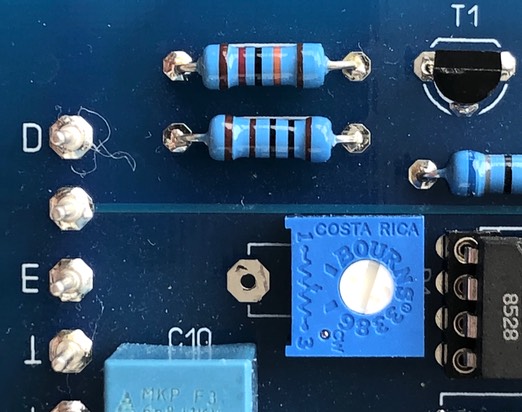

Bend the resistors so that they fit neatly right away:

Solder the diodes on the right position. Note the direction of the black line (component) and tabbed indication (silkscreen). Do not reverse the polarity of these components.

Solder the resistors on the right position:

There are some typo's on the silkscreen: R24 should be read as R42 and R89 should be read as R69. This is only applicable for the prototyping boards.

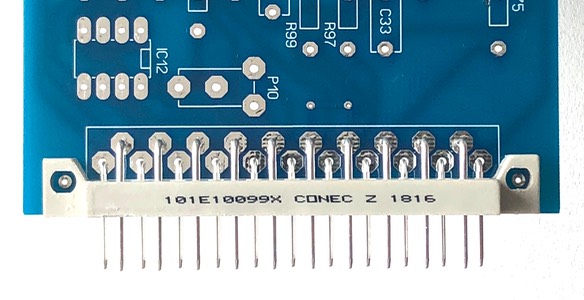

Put the 21 pin connector to the board, do not exert any excessive force:

Solder only pin 1 and pin 21 and check for a right angle. Correct if necessary and solder all remaining pins.

Add also the IC sockets by soldering only 1 pin. Check the direction and alignment of the IC sockets before soldering the remaining pins.

Plug the corresponding IC's into the IC sockets, double check the direction of the notch to avoid destroyed IC's afterwards.

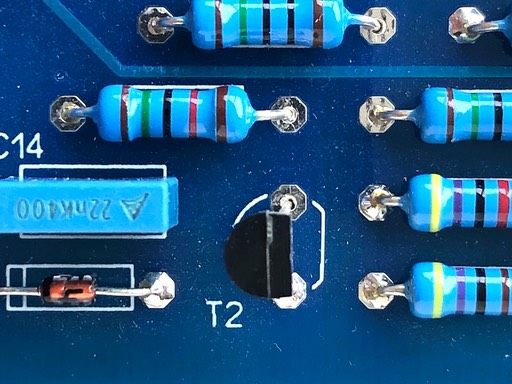

Insert both transistors, do not mix the BC547 and BC548, they look exactly the same.

Solder only 1 of the legs, this allows lining up the components. Watch the direction of the transistor, correct if necessary and solder the remaining legs.

Thereafter add the trimpots for tuning and adjustment of the filter later.

Add the film capacitors.

Only applicable for prototyping boards and depending on the choosen components, bend the capacitor legs as illustrated to adapt the lead spacing:

Finally use a pliers to press all solder pins into the PCB. The solder pins should have a diameter of 1 mm, the holes in the PCB have the same size. So firmly press the pins into the right position.

Thoroughly clean the PCB using flux cleaner and check for bad soldering or tin bulbs.

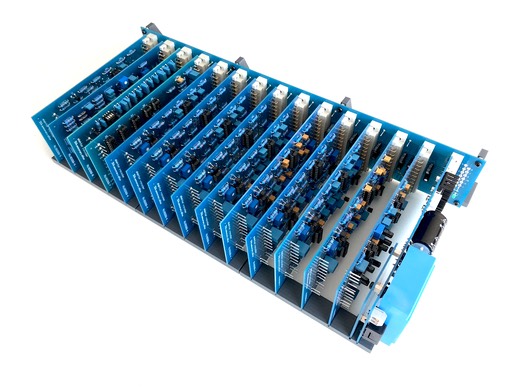

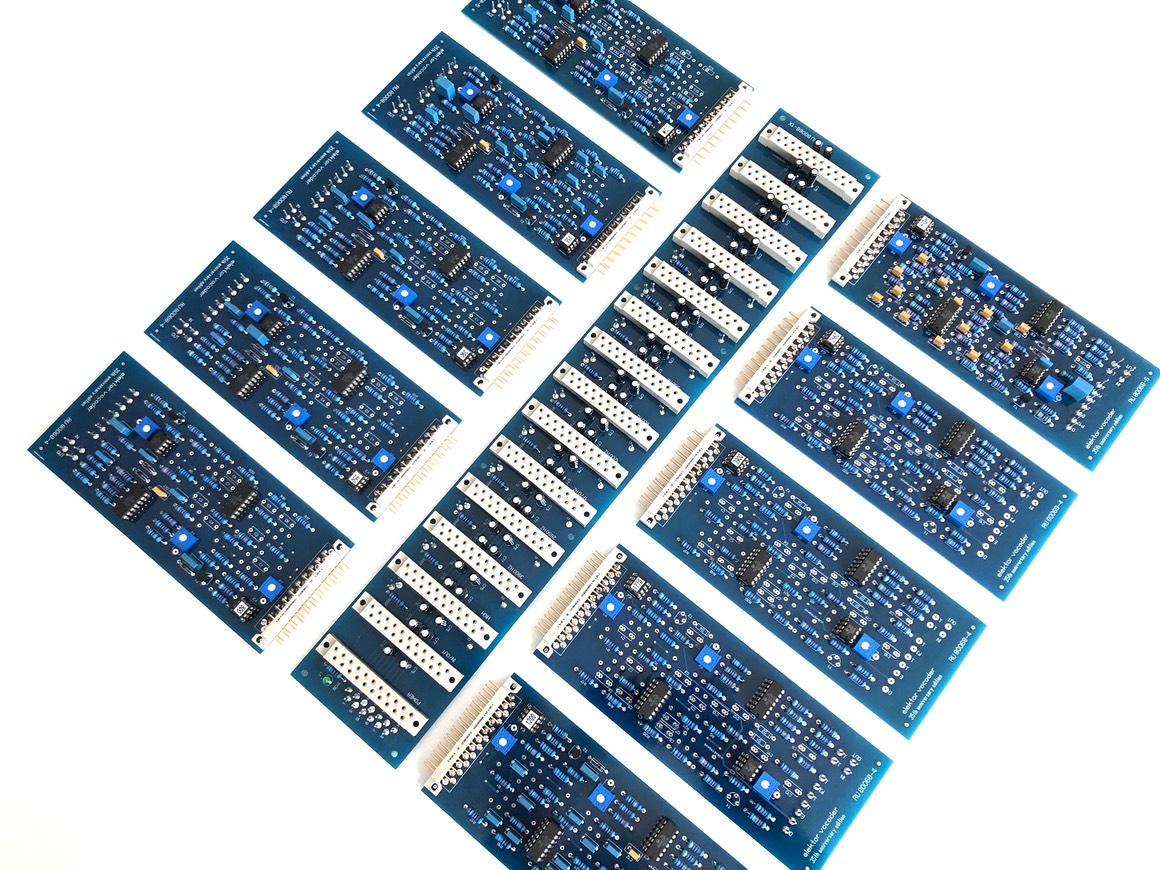

All filters are now ready:

Important remark

If the component ordering was based on the initial BOM (23/09/2018 or 07/11/2018), trimmer P1 had a value of 100 kOhm. Together with the 180 kOhm resistors R200 and R201 this provides a bias control range of -4 .. +4 V on the inverting input of the LM741 opamp. In practice this seems a bit too much to fine-tune the offset in an easy way. The result is that (in case of an inaccurate setting of P1) the opamp immediately saturates.

If the updated BOM (11/02/2019 or later) was used to order all componentns, ignore these instruction, as the correct trimmers are already included.

The hard way is to trim P5 until you measure approximately 0.0 mV on pin 6 of IC7. But there are 3 much simpler solutions to refine this adjustment. Based on your desoldering skills, choose one at your own choice.

Solution 1:

Replace the 100 kOhm potentiometer P5 on the high pass filter by a 10 kOhm equivalent.

In this solution 1 trimmer should be replaced.

Solution 2:

Replace both resistors R200 and R201 on the high pass filter by a 1 MOhm 1% equivalent.

In this solution 2 resistors should be replaced.

Solution 3:

Solder an additional 1/8 Watt 12 kOhm resistor over the 100 kOhm trimmer (solder side).

In this solution no desoldering skills are required.

Well done

Congratulations, you have finished the high pass filter section, click here to navigate back to the building guide.